In today’s world, there are several smart devices and several different filed a which make the use of certain types of protocols like, Profinet, Profibus and Modbus easy. It also makes controlling the complex and huge industrial process easy and better. These are generally called as the DCS system or the Distributed Control System. This makes the product better and efficient and provides better quality by improving reliability.

There are several industries out their like refinery, gas, and oil, power plants, automobiles, water treatment plants and many more which used the DCS system or the Distributed Control System. Here, the smart instruments and the devices are attached and connected directly to their dedicated controller and also with the operator station with the help of a high-speed communication system.

But there are several things that one should know about these DCS systems. Starting from its architecture to the advantages that it provides one with. There are numerous advantages to having a DCS system from a well-known company. You can choose the best DCS system or Siemens DCS system which is available from in the market quite easily. Get the best DCS system from

Siemens DCS System exporter.

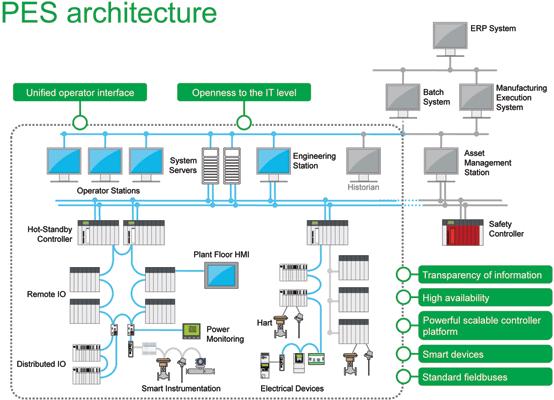

The Architecture Of The Distributed Control System

In a Distributed Control System, we can see that the control system is distributed evenly. These control systems are in small sets and are connected to a subsystem. In turn, the subsystems are well connected to the high-speed communicating buses. These subsystems are further divided into the following.

- Data presentation

- Data Acquisition

- Report Generation

- Process control and supervision

What Are The Advantages Of Distributed Control System?

There are several benefits to using DCS. Some are as follows:

It Handles Complex Structures

The high-speed requirement of the industrial process is controlled by the PLC. There are several limitations to the output and input devices which PLC cannot handle the complex structures sometimes.

Distributed Control System has a distributed controller that is inbuilt and can control different controlling operations also in conditions when you want to expand the input or output. The process of configuring and modifying the controller in a Distributed Control System is quite easy. This is why it can be used for the complex structures well enough.

The System Redundancy

At the entry-level, DCS facilitates the system redundancy. By maintaining the system operation endlessly at the time when some abnormalities occur while the system is still in operation, there can be a rise in the Redundancy of the system.

HMI

Distributed Control System gives you the faculty to control and monitor the equipment of the overall plant is by using HMI. By Alarming facility and Data logging, it gives the operator a better way to understand the process by physical overview.

Scalable Platform

By adding process unit and control unit, you can easily make the structure of Distributed Control System scalable. The Input and output devices can be expanded by adding some modules of Input and output to the controller.

These were some of the benefits of the Distributed Control System. To experience such benefits and advantages get the best Distributed Control System for your company from Siemens DCS System exporter.

|

Leave a Comment